12mm Faston Reducer Solenoid Coil DC12Voltage

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 4-8 Days |

| Packaging: | Boxes, Carton, Pallet |

|---|---|

| Productivity: | 450000 pcs per month |

| Brand: | Brando |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Ningbo China |

| Supply Ability: | 110000 pcs per week |

| Certificate: | CE |

| Port: | Ningbo,Shanghai,Yiwu |

Basic Info

Model No.: BB12133111

Click on the follow link to find out more information: https://www.brandopneumatic.com/solenoid-coil/

Company Info

- Company Name: NINGBO BRANDO HARDWARE CO.,LTD

- Representative: Lu Jin Jun

- Product/Service: Solenoid Valve , Solenoid Valve Coil , Solenoid Valve Armature , Pulse Jet Valve , Refrigeration Solenoid Valve , Pneumatic Solenoid Valve

- Capital (Million US $): 1000,000RMB

- Year Established: 2008

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 10

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: Ningbo

- Contact Person: Mr. Brandon Bao

- Tel: 86-0574-83879820

Premium Related Products

Other Products

Hot Products

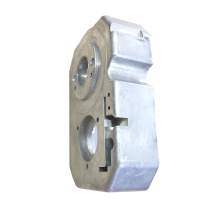

Made in China Metal Casting Automobile PartsAluminium High Pressure Die Casting Radiator MouldAluminum Pressure Die Casting Rotor (SW359E)Aluminum Die Casting Outdoor Communicator Housing (SW060C)OEM Aluminum Metal Casting of Motor HousingOEM Aluminum Die Cast Components Gearbox HousingAluminum Heating Appliances ReadiatorDie Casting Mould/ Mold for Aluminum Radiator (SW220M)South-eastern Asian Style Air ChucksMetal Flexible ExtensionTOYOTA FUEL FILTER 233900L010, 23390-0L010,23390OL010,23390-OL010, 233900L011,23390-L020,23390-0L010,2339030200 HiLux ,LEXUSOil/Lube Filter element 2761800009,2761840025 Fits Mercedes Benz C300/C350/CL550/E350/E550/GL450Types of fuel filter For MITSUBISHI L300/FD20/S4S. MB554950,MB55490,MB220900,552233,MB29677,MB129677Car oil filter manufacture 15208-31U01,15208-7B000,15208-31000,15208-31U00 OIL FILTERToyota Air Filter OE 17801-BZ050,17801BZ050hot sale die casting mould custom